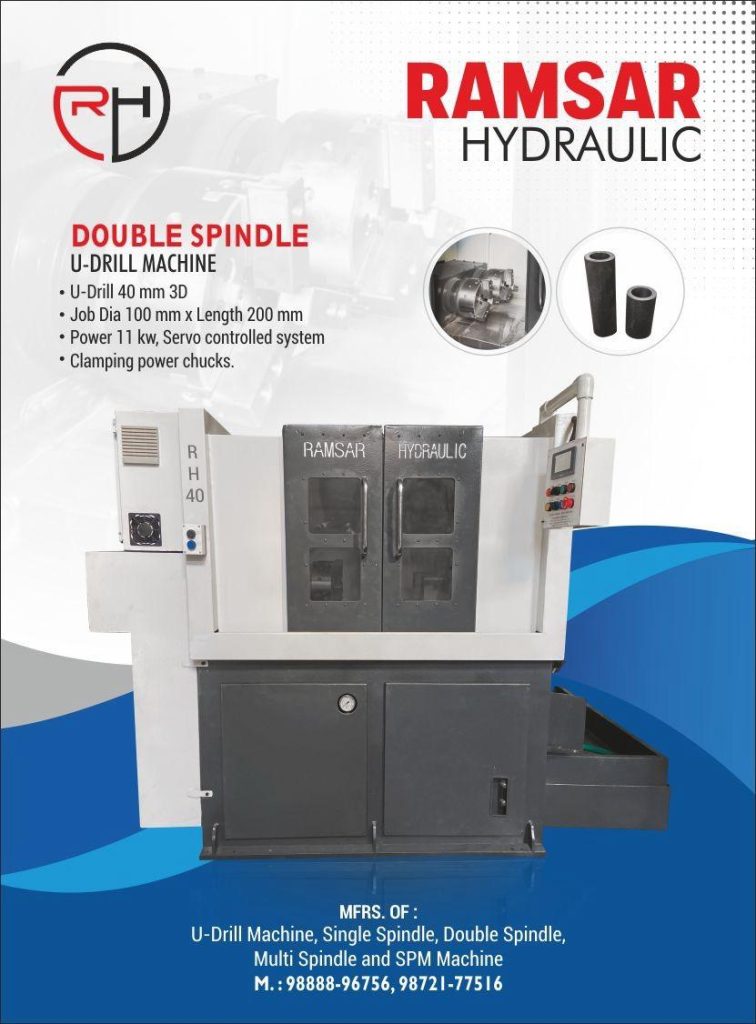

Double Spindle U-Drill Machine

1. Overview

Ramsar Hydraulic is well-known company in the field of : Double Spindle U-Drill Machine Manufacturers. A Double Spindle U-Drill Machine Manufacturers is a high-performance metal cutting machine designed for simultaneous drilling operations using U-type indexable insert drills. It is primarily used in mass production environments where multiple identical holes are required with high accuracy, reduced cycle time, and consistent quality.

This machine features two independent or synchronized spindles, each equipped with a U-drill tool, enabling the drilling of two holes in one setup or at the same time.

- Base & Column:

Heavy-duty cast iron or fabricated steel base designed to absorb vibration and ensure stability during twin drilling operations. - Double Spindle Head:

- Two spindles mounted parallel to each other.

- Both spindles are powered by individual motors (or one shared motor with dual drive shafts).

- Equipped with precision bearings for high-speed and high-torque performance.

- Feed Mechanism:

Servo or hydraulic feed system controls spindle advancement and retraction. Feed rates can be set independently for each spindle. - Tooling (U-Drills):

- Each spindle holds a U-shaped indexable insert drill.

- Designed for fast metal removal with internal coolant supply.

- Replaceable carbide inserts reduce downtime and tooling cost.

- Coolant System:

Through-spindle coolant system ensures effective chip evacuation and improved tool life. - Workholding Fixture:

Custom-designed fixture for holding workpieces securely and accurately in alignment with both spindles. - Control Panel (if CNC-controlled):

Digital interface or CNC system allows programming of spindle speeds, feeds, and depth of drilling.

🛠️ Types of Multi-Spindle Drill Machines

- Fixed Type:

- Spindle positions are fixed (used for identical hole patterns).

- Common in mass production where the part design doesn’t change.

- Adjustable Type:

- Spindles can be repositioned within a certain range.

- Suitable for batch production with varying hole layouts.

- Automatic Type:

- Equipped with automatic feed, tool change, or indexing mechanisms.

- Often part of CNC or transfer lines.