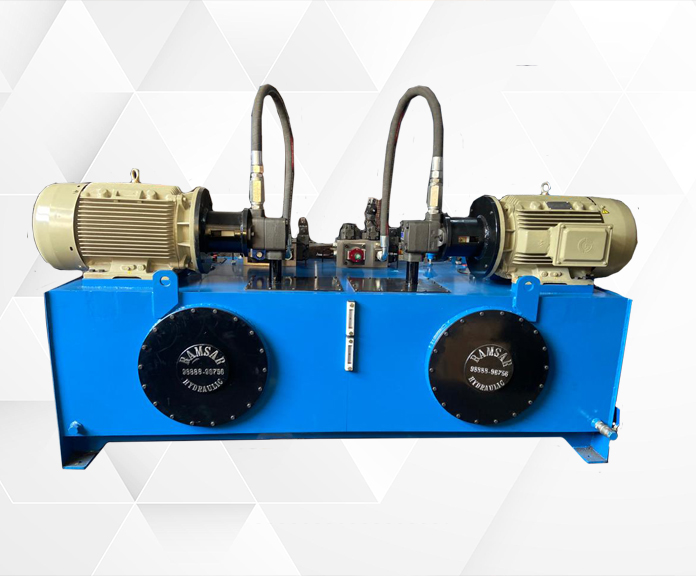

Hydraulic Power Pack Manufacturer and Exporter in Ludhiana Punjab India.

Ramsar Hydraulic is a Quality manufacturer and Exporter of Best Hydraulic Power packs and Machinery in Ludhiana Punjab India. A hydraulic power pack, also known as a hydraulic power unit (HPU), is a self-contained system that generates hydraulic power to operate machinery or equipment. It consists of various components that work together to provide the necessary force to drive hydraulic machinery.

Manufacturing a hydraulic power pack involves several stages and processes, typically following these steps:

- Design and Engineering: The process starts with design and engineering where the specifications and requirements of the hydraulic power pack are outlined. This involves understanding the intended application, required power, flow rates, pressure levels, and environmental factors.

- Component Selection: Based on the design specifications, manufacturers select components such as pumps, motors, reservoirs, valves, filters, coolers, and other necessary parts. Components are chosen for their compatibility, efficiency, and durability.

- Assembly: Assembly involves integrating selected components into a frame or housing to create the hydraulic power pack. This can be a modular design where components are assembled together or custom-built to fit specific requirements.

- Hydraulic Circuitry: The assembly includes creating the hydraulic circuitry, which involves connecting hoses, tubes, and fittings to ensure proper flow of hydraulic fluid between components.

- Testing and Quality Control: Once assembled, the power pack undergoes rigorous testing to ensure that it meets performance standards, operates efficiently, and is free from leaks or defects. Quality control measures are implemented to maintain consistency and reliability.

- Painting and Finishing: After testing and inspection, the power pack might undergo painting or finishing processes to protect against corrosion or environmental damage, depending on the intended use and environmental conditions.

- Packaging and Shipping: The final step involves packaging the hydraulic power pack securely for transportation to customers or distribution centers. Proper packaging ensures that the unit arrives safely without damage.

Manufacturers often follow industry standards and regulations during the manufacturing process to ensure safety, efficiency, and compliance with quality standards. They might also offer customization options to tailor power packs for specific applications based on customer needs.

Efficient manufacturing requires expertise in hydraulic systems, engineering, and quality control to produce reliable and high-performance hydraulic power packs for various industrial and commercial uses.